We lead the industry as a top spray dryer manufacturers, committed to providing cutting-edge solutions for your drying needs. Our spray dryers convert liquids into fine powders efficiently, ensuring consistent quality and performance. Whether you need a laboratory spray dryer or an industrial spray dryer, we offer a comprehensive range of spray drying equipment designed to meet your specific requirements. Let’s explore how our advanced technology and expertise can revolutionize your drying process.

Discover the perfect drying solution with Acmefil — Let’s tailor a spray dryer to fit your needs exactly. Contact us today and transform your production process!

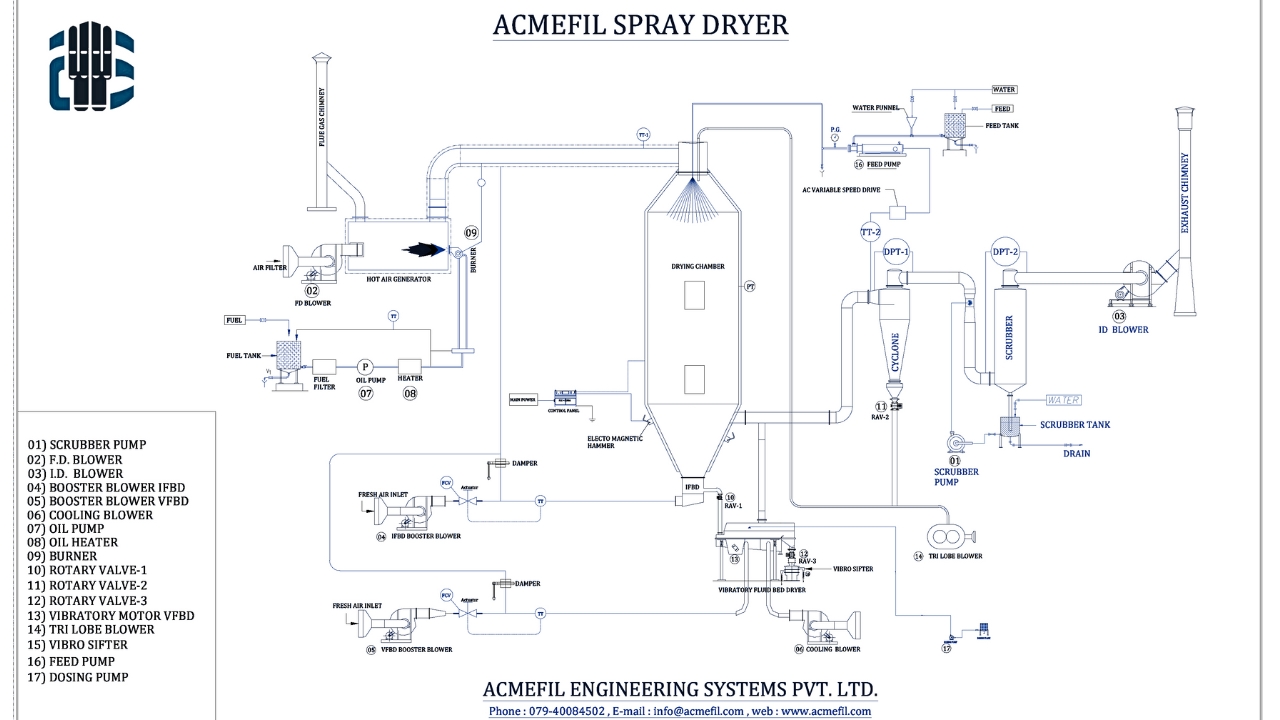

Spray drying transforms liquid feed into dry powder using a versatile and efficient method. This process involves atomizing the liquid feed into fine droplets, which then come into contact with hot air. The rapid drying process ensures that moisture evaporates almost instantly, leaving behind dry powder particles. Our spray dryer machines optimize this process, ensuring uniform particle size, enhanced product stability, and superior quality.

As a leader in spray dryer manufacturing, Acmefil offers a diverse range of spray dryer machines tailored to various industrial needs. Our machines are known for their robustness, efficiency, and precision. Here are some key features of our spray dryers:

Our industrial spray dryers handle large-scale drying applications across various industries, including food processing, pharmaceuticals, and chemicals. These robust machines ensure high capacity and efficiency, making them ideal for large-scale production. Key benefits include:

For research and development, our laboratory spray dryers offer precise control and flexibility. These compact units are perfect for small-scale production, pilot trials, and product testing. Key features include:

We understand the importance of pilot trials in validating the feasibility and efficiency of the spray drying process. Our spray dryer pilot trial plants offer a practical solution for testing and optimizing your drying process before scaling up to full production. Benefits include:

At Acmefil, we offer competitive spray dryer prices without compromising on quality. Our pricing reflects the value and reliability of our equipment, ensuring you get the best return on your investment. Factors influencing our spray dryer prices include:

As a leading spray dryer manufacturer, Acmefil stands out for our commitment to quality, innovation, and customer satisfaction. Here’s why you should choose us for your spray drying needs:

Ready to take your drying process to the next level with Acmefil’s advanced spray dryers? Contact us today to discuss your specific requirements, request a quote, or schedule a pilot trial. Our team of experts is here to help you find the perfect drying solution for your business.

Acmefil is a leading spray dryer manufacturer in India, renowned for delivering high-quality and efficient drying solutions to various industries. Our advanced spray drying technology ensures optimal performance, energy efficiency, and consistent product quality. With a strong commitment to innovation and customer satisfaction, Acmefil offers customized solutions tailored to meet the specific needs of each client. Our team of experienced professionals works diligently to provide robust and reliable spray dryers that enhance productivity and reduce operational costs. Choose Acmefil for cutting-edge spray drying equipment that sets the benchmark in the industry.

For more knowledge about spray dryers, you can explore our knowledge hub for spray drying technology at www.spraydryer.com

Spray drying produces powdered milk, coffee, tea, eggs, flavorings, and pharmaceuticals. This process creates dry powders from liquid suspensions, emulsions, or solutions, ensuring consistent particle size and moisture content.

Yes, spray drying is cost-effective, especially for large-scale production. It offers high efficiency, minimizes product loss, and handles heat-sensitive materials effectively. By converting liquids to powders in a single step, it reduces processing time and energy consumption.

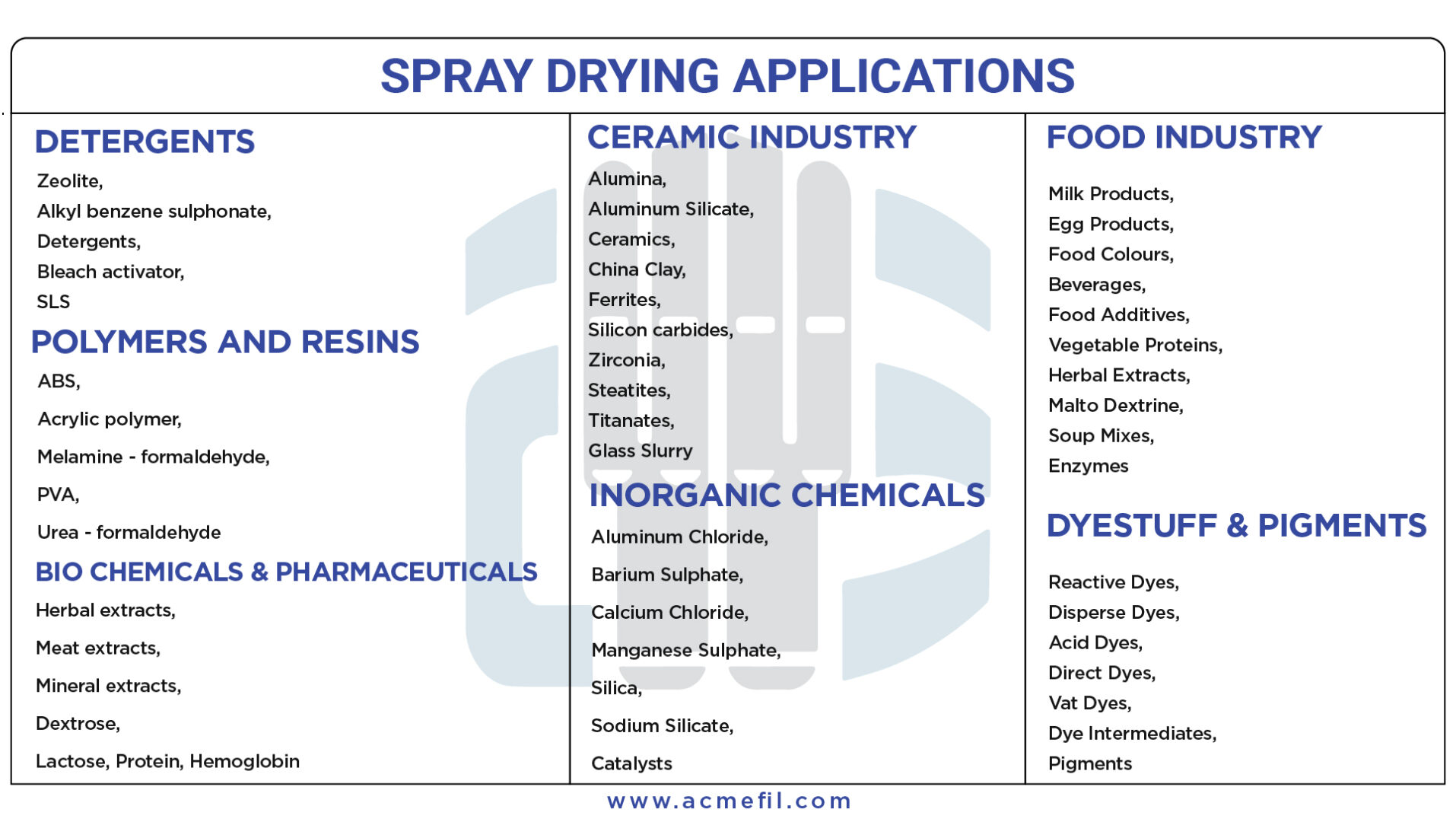

Spray dryers serve various industrial applications, including the food, pharmaceutical, and chemical industries. They produce powdered food products, active pharmaceutical ingredients (APIs), and specialty chemicals. Their ability to create uniform particles makes them ideal for these applications.

Acmefil manufactures high-quality spray dryers in India. With over 30 years of experience, we offer efficient drying solutions tailored to meet various industrial needs.

Spray drying converts a liquid feed into a dry powder by rapidly drying it with hot gas. The process atomizes the liquid, mixes it with hot air, and dries the droplets into fine particles. This method ensures precise control over particle size and moisture content, producing consistent, high-quality powders.

They’re popular because they can quickly turn liquids into dry powders, which is handy in making a wide range of products.