Home » Other Products » Air Lock Rotary Valve

Air Lock Rotary Valve

Air lock rotary valves are essential components in numerous industrial systems, playing a critical role in managing material flow while maintaining air pressure and system efficiency. These devices are integral to the operation of pneumatic conveying systems, dust collection units, and various bulk material handling processes.

How Air Lock Rotary Valves Work

Air lock rotary valves function by rotating a pocketed rotor within a housing to transfer solid materials from one chamber to another while maintaining a tight air seal. This operation not only controls the flow of materials but also prevents air from leaking across the system’s inlet and outlet, ensuring optimal performance in systems requiring precise air pressure management.

Key Components

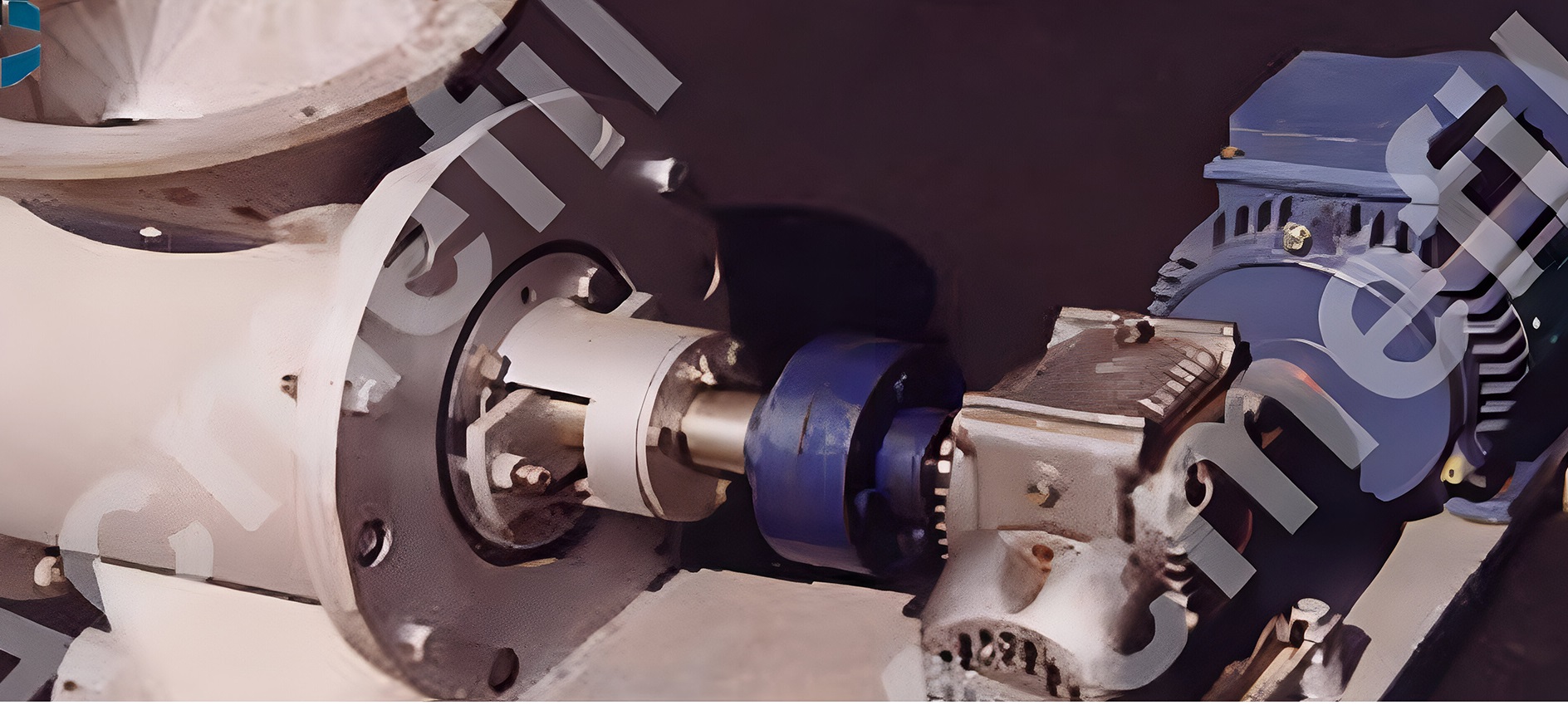

- Rotor: The rotating part with pockets that carry materials through the valve.

- Housing: The casing that contains the rotor, designed to ensure minimal air leakage.

- Drive Mechanism: Typically a motor, which powers the rotor’s rotation at desired speeds.

- Seals and Bearings: Ensure smooth operation and maintain the airlock integrity.

Advantages of Using Air Lock Rotary Valves

- Efficiency: Improves system efficiency by minimizing air leakage and optimizing material flow.

- Durability: Built to withstand tough conditions and abrasive materials.

- Versatility: Can handle a wide range of materials, from fine powders to large granules.

- Control: Allows precise control over material flow rates.

Applications in Industries

- Food Processing: Used in systems for handling grains, flour, sugar, and other bulk food ingredients.

- Pharmaceuticals: Integral in handling and processing bulk powders and ensuring contamination-free operations.

- Chemical Manufacturing: Facilitates the safe and efficient transfer of chemical granules and powders.

- Cement and Mining: Critical for dust control systems and material handling in harsh environments.

Installation and Maintenance

Proper installation is crucial for maximizing the performance and lifespan of air lock rotary valves. It involves ensuring alignment with the conveying system and securing all connections. Regular maintenance includes:

- Routine inspection of the rotor, seals, and bearings.

- Cleaning to prevent material build-up that can affect performance.

- Lubrication of moving parts to ensure smooth operation.

Why Choose Our Air Lock Rotary Valves?

Our air lock rotary valves are engineered with precision and constructed from high-quality materials, offering superior performance and reliability. We provide:

- Custom configurations to fit specific system requirements.

- Robust construction suitable for various industrial environments.

- Exceptional customer service and technical support.

Explore our website for in-depth product details, operational guides, and real-world applications of our air lock rotary valves. We are dedicated to providing solutions that enhance your operational efficiency and process reliability.

Applications

- Milk concentrate from 8 - 10% upto 45%

- Effluent concentrate before incineration

- Weak liquor low temperature concentration

- Dilute Caustic lye solution concentration

- Herbal extract concentration

- Fruit juice concentration

General FAQ

A sludge dryer is a machine used for reducing the moisture content in sludge, transforming it from a semi-solid to a dry, manageable form for easier handling and disposal.

Dried sludge is often used as a fuel source, in agricultural applications as fertilizer, or disposed of in landfills.