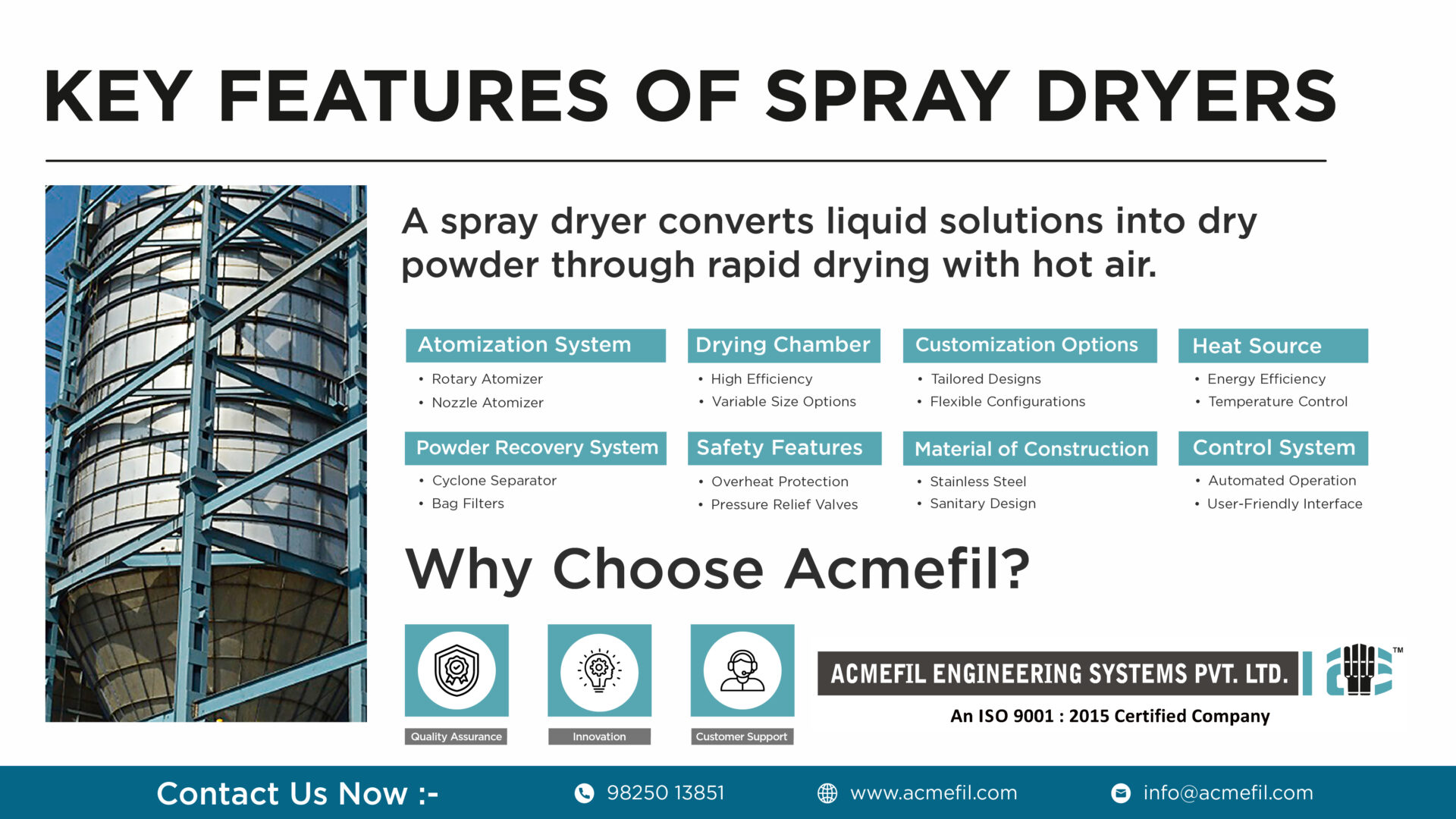

At Acmefil, we design and manufacture high-quality spray dryers that cater to diverse industrial needs. Our spray dryers stand out due to their advanced features and exceptional performance. Let’s explore the key features that make our spray dryers the preferred choice for businesses across various industries.

Advanced Atomization Techniques

We utilize advanced atomization techniques to ensure fine and uniform droplet formation. With both rotary and nozzle atomization options, you get consistent particle size and enhanced product quality.

Efficient Drying Chambers

Our drying chambers maximize heat transfer and minimize energy consumption. The optimized airflow and temperature control within the chamber ensure rapid and uniform drying, resulting in superior product quality.

Customizable Process Parameters

You can adjust temperature, airflow, and feed rate to suit different products. Our spray dryers offer customizable process parameters, ensuring optimal drying conditions for a wide range of applications, from food and beverages to pharmaceuticals and chemicals.

High-Quality Material Construction

We use high-quality stainless steel and robust materials in our spray dryers, ensuring durability and easy cleaning. This construction meets stringent industry standards, making our spray dryers ideal for the food, pharmaceutical, and chemical industries.

Automated Control Systems

Our spray dryers feature advanced automated control systems with user-friendly interfaces. These systems allow you to precisely monitor and control the drying process, increasing operational efficiency and reducing manual intervention.

Energy Efficiency

Our spray dryers include energy-saving features that reduce power consumption without compromising performance. The efficient heat recovery systems and optimized airflow design contribute to lower operational costs and a smaller carbon footprint.

Scalability

Whether you run a small-scale operation or a large industrial plant, our spray dryers offer scalability to meet your production needs. We provide models with varying capacities, ensuring you can scale up or down based on your business requirements.

Enhanced Safety Features

Safety is paramount in industrial operations. Our spray dryers incorporate multiple safety features, including:

- Temperature and pressure sensors

- Emergency shutdown systems

- Robust construction to prevent leaks and spills

These features ensure safe and reliable operation, protecting both your workforce and your investment.

Versatility in Applications

Our spray dryers are versatile, suitable for a wide range of applications:

- Milk powder production

- Coffee drying

- Pharmaceutical powders

- Chemical processing

- And more!

This adaptability makes our spray dryers a valuable asset for any industry.

Superior Product Quality

Our goal is to produce high-quality end products. Our spray dryers maintain the integrity of the original material by providing a controlled drying environment. This preserves nutritional value, flavor, and active ingredients, resulting in a premium final product.

Conclusion

Acmefil’s spray dryers combine advanced technology, efficiency, and versatility to meet the diverse needs of modern industries. With features like advanced atomization, customizable process parameters, energy efficiency, and robust safety measures, our spray dryers stand out as the best choice for businesses aiming to enhance their production processes.

For more information on how our spray dryers can benefit your business, contact us today and discover the Acmefil difference!