When you need efficient and rapid drying solutions, flash dryers stand out as one of the most effective technologies available. At Acmefil, we take pride in being leading flash dryer manufacturers. We offer top-of-the-line products that cater to a wide range of industrial drying needs. Flash dryers are designed for high-speed drying of fine materials and heat-sensitive products, ensuring optimal performance and energy efficiency. Our commitment to innovation and quality has positioned us as industry leaders. We provide our clients with reliable, durable, and high-performing drying solutions. Whether you are in the food industry, pharmaceuticals, chemicals, or minerals processing, our flash dryers meet your specific requirements and exceed your expectations.

A flash dryer uses a stream of hot air to quickly dry materials suspended in it. This continuous drying system works perfectly for products like powders, granules, and pastes that need rapid moisture removal. Flash dryers disperse the wet material into a high-velocity air stream. This process immediately evaporates the moisture content, resulting in a dry product within seconds.

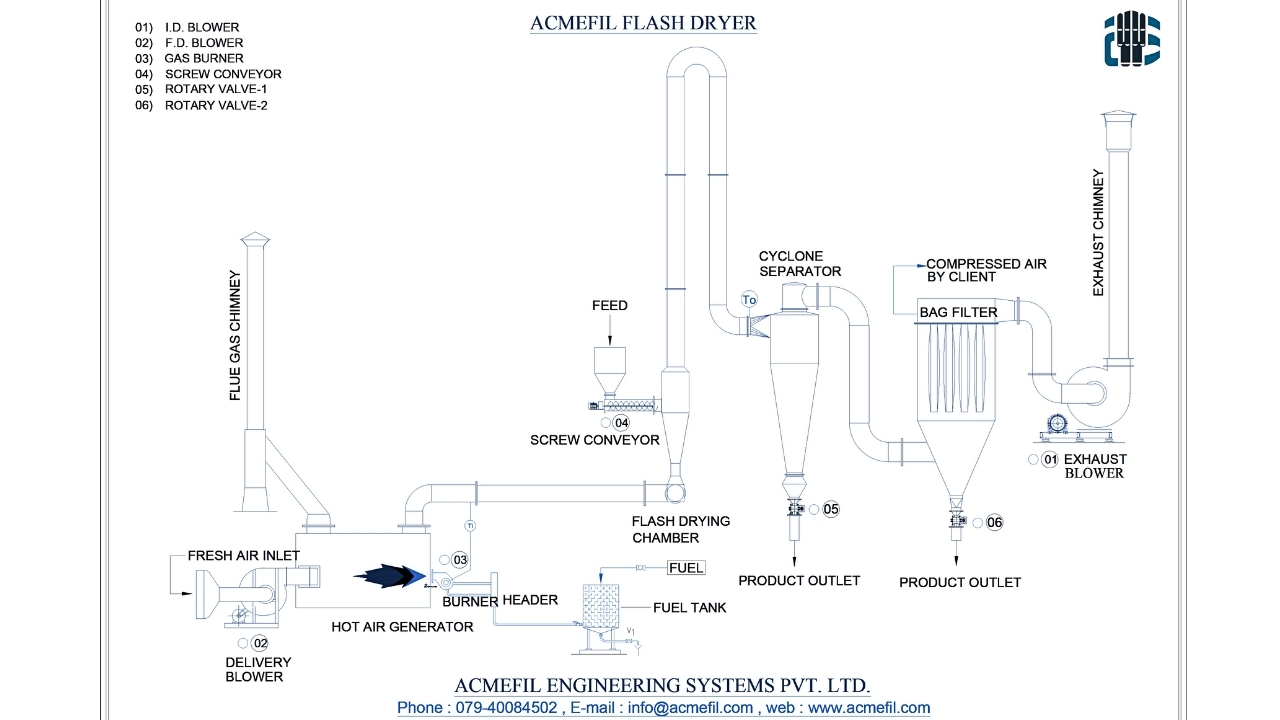

Flash dryers operate on a simple yet highly effective principle. Here’s how they work:

You begin by feeding the wet material into the flash dryer. The feeding system, which can include a screw feeder, rotary valve, or pneumatic conveyor, introduces the material into the drying chamber.

The dryer generates hot air using a heater, typically fueled by gas, oil, or electricity. The system heats the air to a temperature suitable for drying the specific material. You can adjust the temperature based on the moisture content and thermal sensitivity of the material.

Inside the drying chamber, the system disperses the wet material into the high-velocity hot air stream. This dispersion ensures that the material particles are fully exposed to the hot air, maximizing the drying efficiency.

As the material particles come into contact with the hot air, the moisture within the particles rapidly evaporates. This process happens almost instantaneously due to the high temperature and the velocity of the air stream. The evaporated moisture exits the system with the exhaust air.

The dried material, now reduced in moisture content, is separated from the air stream using a cyclone separator or a bag filter. These components ensure that the dry particles are collected efficiently, while the moist air is expelled from the system.

Flash dryers are equipped with advanced control systems that monitor and regulate the drying process. These systems adjust the air temperature, airflow rate, and material feed rate to ensure consistent and optimal drying performance.

As a premier flash dryer manufacturer, we at Acmefil ensure that our products deliver numerous benefits, including:

1. Rapid Drying: Flash dryers dry materials quickly, significantly reducing processing time compared to other drying methods. This rapid drying capability proves essential for industries that require fast turnaround times.

2. Energy Efficiency: Our flash dryers maximize energy efficiency, using minimal energy to achieve maximum drying results. This efficiency leads to cost savings and a reduced environmental footprint.

3. Uniform Drying: Flash dryers ensure that materials dry evenly, maintaining consistent product quality. This uniformity proves crucial for preserving the integrity of heat-sensitive materials.

4. Versatility: Flash dryers handle a variety of materials, from powders and granules to pastes and slurries. This versatility makes them suitable for diverse industrial applications, including food processing, pharmaceuticals, chemicals, and minerals.

At Acmefil, we engineer our flash dryers with advanced features to meet the highest industry standards. Some key features include:

1. High-Performance Design: Our flash dryers have a high-performance design that ensures efficient drying of various materials. The robust construction and superior components guarantee longevity and reliable operation.

2. Customizable Options: We understand that different industries have unique drying requirements. Therefore, we offer customizable options to tailor our flash dryers to specific needs. This includes adjustable airflow, temperature control, and various material handling systems.

3. Easy Maintenance: We design Acmefil flash dryers for easy maintenance, with accessible components and user-friendly interfaces. This reduces downtime and ensures your production line runs smoothly.

4. Safety Features: We prioritize safety at Acmefil. Our flash dryers include multiple safety features, such as temperature sensors, emergency shut-off systems, and protective enclosures, ensuring safe and reliable operation.

Acmefil stands out as a trusted flash dryer manufacturer for several reasons:

With decades of experience in the industry, we at Acmefil understand drying technologies and industrial needs deeply. Our expertise allows us to design and manufacture flash dryers that meet the highest standards of performance and reliability.

Quality lies at the heart of everything we do at Acmefil. Our flash dryers undergo rigorous testing and quality control measures to ensure they meet industry standards and exceed customer expectations.

We believe in building long-term relationships with our clients. Our dedicated customer support team is always available to assist with any queries or issues, providing timely and effective solutions.

Innovation drives us at Acmefil. We continually invest in research and development to enhance our products and introduce new technologies that benefit our customers. Our commitment to innovation ensures that you get the latest and most efficient drying solutions.

Selecting the right flash dryer for your application is crucial for achieving optimal drying results. Here are some factors to consider:

Understand the properties of the material you need to dry, including particle size, moisture content, and heat sensitivity. This information helps determine the appropriate drying parameters and equipment specifications.

Consider your production requirements and choose a flash dryer that can handle the desired throughput. Acmefil offers a range of flash dryers with varying capacities to suit different production needs.

Evaluate the energy consumption of the flash dryer and opt for energy-efficient models to minimize operating costs. Acmefil’s flash dryers are designed for optimal energy efficiency without compromising performance.

Look for flash dryers that offer customizable features to match your specific process requirements. Acmefil provides tailored solutions to ensure our flash dryers meet your unique needs.

Acmefil leads the way as a flash dryer manufacturer, providing high-quality, efficient, and reliable drying solutions for various industries. Our flash dryers feature advanced designs that ensure rapid and uniform drying, energy efficiency, and versatility. With our expertise, commitment to quality, and customer-focused approach, we are your trusted partner for all your drying needs.

If you seek top-notch flash dryers that deliver exceptional performance, look no further than Acmefil. Contact us today to learn more about our products and how we can help you achieve your drying goals.

A flash dryer is a drying machine used for rapid drying of wet particles, powders, or pastes. It works by mixing the wet material with a stream of hot air, causing the moisture to evaporate quickly. The process is very fast, typically lasting only a few seconds, which is why it’s called “flash” drying. This method is effective for materials that are heat-sensitive or need to be dried quickly to maintain quality. It’s widely used in industries like food, chemical, and mineral processing.

Flash drying works by rapidly drying wet materials with a hot air stream. The material is dispersed into a hot air flow, where the intense heat causes rapid evaporation of moisture. This quick drying process usually takes just a few seconds, making it suitable for heat-sensitive or easily degradable materials.

Consider factors like material characteristics, production capacity, energy consumption, and available customization options.

Yes, flash dryers are designed to maximize energy efficiency, reducing operating costs and environmental impact.

Yes, you can customize flash dryers to match specific process requirements, including adjustable airflow, temperature control, and material handling systems.

Flash dryers are designed for easy maintenance with accessible components and user-friendly interfaces, minimizing downtime.

Flash dryers include safety features like temperature sensors, emergency shut-off systems, and protective enclosures to ensure safe operation.

Acmefil offers expertise, quality assurance, innovative solutions, and dedicated customer support, making us a trusted choice for flash drying needs.

| Applications | Applications |

|---|---|

| Drying of Vegetable Protein | Drying of Spent Tea |

| Drying of Wheat Starch | Drying of Soybean Protein |

| Drying of Meat Residue | Drying of Flour |

| Drying of Cement | Drying of Aniline Dyes |

| Drying of Blowing Agents | Drying of Coal Dust |

| Drying of Bread Crumbs | Drying of Cornstarch |

| Drying of Corn Gluten | Drying of Casein |

| Drying of Gravy Powder | Drying of Soup Powder |

| Drying of Chlorinated | Drying of Rubber |

| Drying of Copper Oxide | Drying of Gypsum |