Home » Fluid Bed Dryer » Vibratory Fluid Bed Dryer

Welcome to Acmefil! We manufacture advanced drying solutions and specialize in various high-quality dryers, including the highly efficient and versatile vibratory fluid bed dryer, also known as the vibratory fluidized bed dryer. We take pride in our cutting-edge technology and commitment to excellence, making us a leading name in the industry. With extensive experience and dedication to customer satisfaction, we ensure that every product we deliver meets the highest performance and reliability standards. Whether you need to dry pharmaceuticals, food products, chemicals, or minerals, Acmefil has the perfect solution for your drying needs.

A vibratory fluid bed dryer, or vibratory fluidized bed dryer, utilizes vibrations to fluidize particles, enhancing the drying process. Industries such as pharmaceuticals, chemicals, food, and minerals widely use this technology due to its efficiency and effectiveness in drying granular and powdery materials.

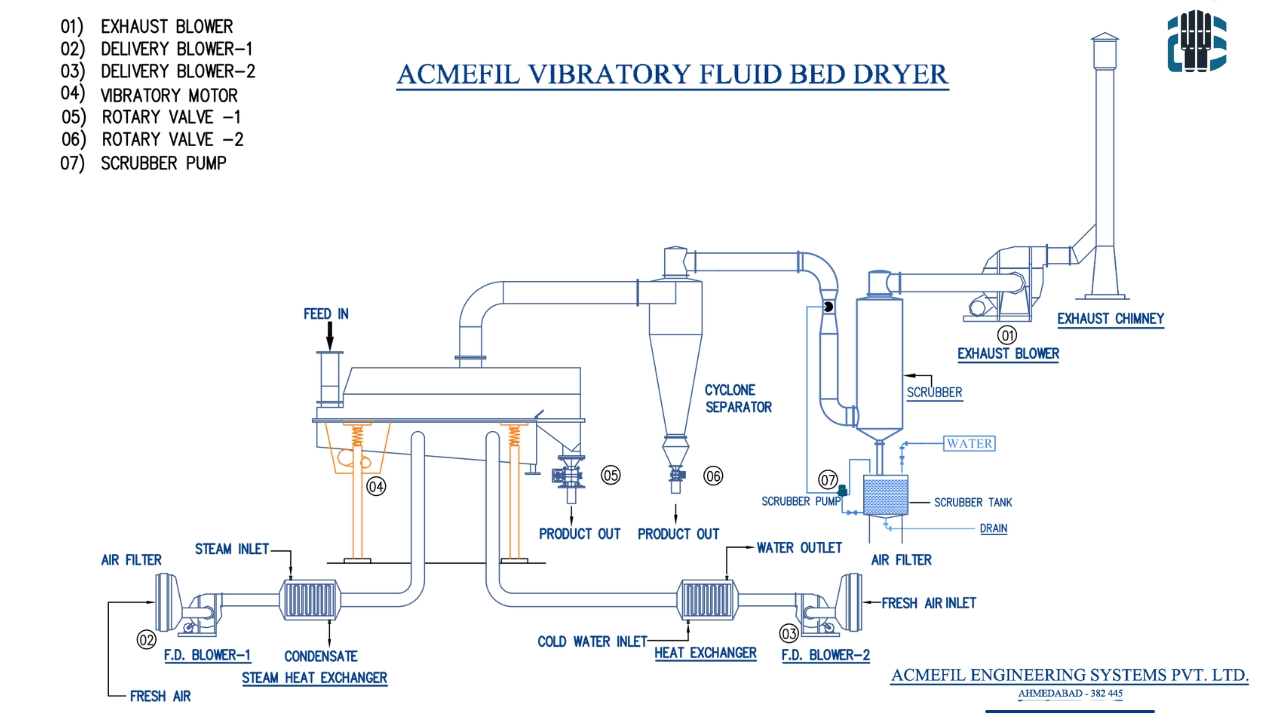

We design the vibratory fluid bed dryer (VFBD) to operate by introducing a controlled flow of hot air or gas through a perforated plate. As the air passes through the material bed, it fluidizes the particles, creating a suspended state. The vibratory motion enhances this fluidization, ensuring uniform drying and efficient heat transfer. This process allows for the precise control of drying parameters, resulting in high-quality dried products.

In the pharmaceutical industry, vibratory fluid bed dryers are essential for drying granules and powders used in tablet production. The controlled drying environment ensures uniform moisture content, which is crucial for the stability and effectiveness of pharmaceutical products. This technology is particularly beneficial for drying heat-sensitive materials, as it allows for precise temperature control.

The food industry benefits from vibratory fluidized bed dryers for drying various food products, including grains, cereals, and snacks. The gentle drying process preserves the nutritional value and texture of the food items. Additionally, the ability to control drying parameters helps maintain the flavor, color, and overall quality of the food products.

Chemical industries utilize vibratory fluid bed dryers to dry and cool chemical powders and granules. The precise temperature control prevents degradation and ensures the purity of the chemical compounds. This technology is ideal for drying hygroscopic materials that are sensitive to moisture.

In the minerals industry, vibratory fluidized bed dryers are used to dry minerals and ores. The efficient drying process reduces moisture content, making the materials suitable for further processing or packaging. This technology is particularly effective for drying fine powders and granules, which require uniform moisture removal.

At Acmefil, we provide exceptional after-sales service to ensure the optimal performance and longevity of your vibratory fluid bed dryer. Our comprehensive service offerings include:

Proper maintenance is essential to ensure the longevity and efficiency of your vibratory fluid bed dryer. Here are some maintenance tips:

Acmefil’s vibratory fluid bed dryers (VFBD), also known as vibratory fluidized bed dryers, offer an advanced and efficient solution for drying a wide range of materials. Our commitment to quality, innovation, and customer satisfaction makes us the preferred choice for industries worldwide. Contact us today to learn more about our vibratory fluid bed dryers and how they can enhance your drying processes.

Invest in Acmefil’s vibratory fluidized bed dryers for a reliable, efficient, and customizable drying solution that meets your specific needs. With our expertise and cutting-edge technology, we guarantee superior performance and exceptional results.

For more information or to request a quote, please visit our website or contact our sales team. Let Acmefil be your partner in achieving optimal drying efficiency and quality.

It introduces hot air through a perforated plate, fluidizing the particles and allowing for uniform drying and efficient heat transfer.

The full form of VFBD is “Vibratory Fluidized Bed Dryers and Vibratory Fluidized Bed Dryers.”

It consumes less energy than traditional drying methods, making it a cost-effective solution.

Regular inspections, cleaning, lubrication, calibration, and timely replacement of worn parts are essential for optimal performance.

Yes, we offer comprehensive after-sales service, including commissioning, spare parts, on-site support, annual maintenance contracts, and repairs.

You can visit our website or contact our sales team for more information or to request a quote.