Home » Evaporator » Falling Film Evaporator

Falling film evaporators are essential equipment in various industries, designed to handle the efficient and effective evaporation of liquids. At Acmefil, we take immense pride in being leading manufacturers and suppliers of falling film evaporators. We engineer our products with precision to ensure optimal performance, reliability, and energy efficiency. Our commitment to quality and innovation drives us to provide the best solutions for your evaporation needs.

We understand the critical role falling film evaporators play in your operations, and we dedicate ourselves to delivering equipment that meets and exceeds your expectations. Whether you’re in the food and beverage, pharmaceutical, chemical, or wastewater treatment industry, our falling film evaporators will enhance your processes, improve product quality, and reduce operational costs.

At Acmefil, we design our falling film evaporators to meet the unique requirements of each industry, offering:

Falling film evaporators are versatile and find applications across various industries:

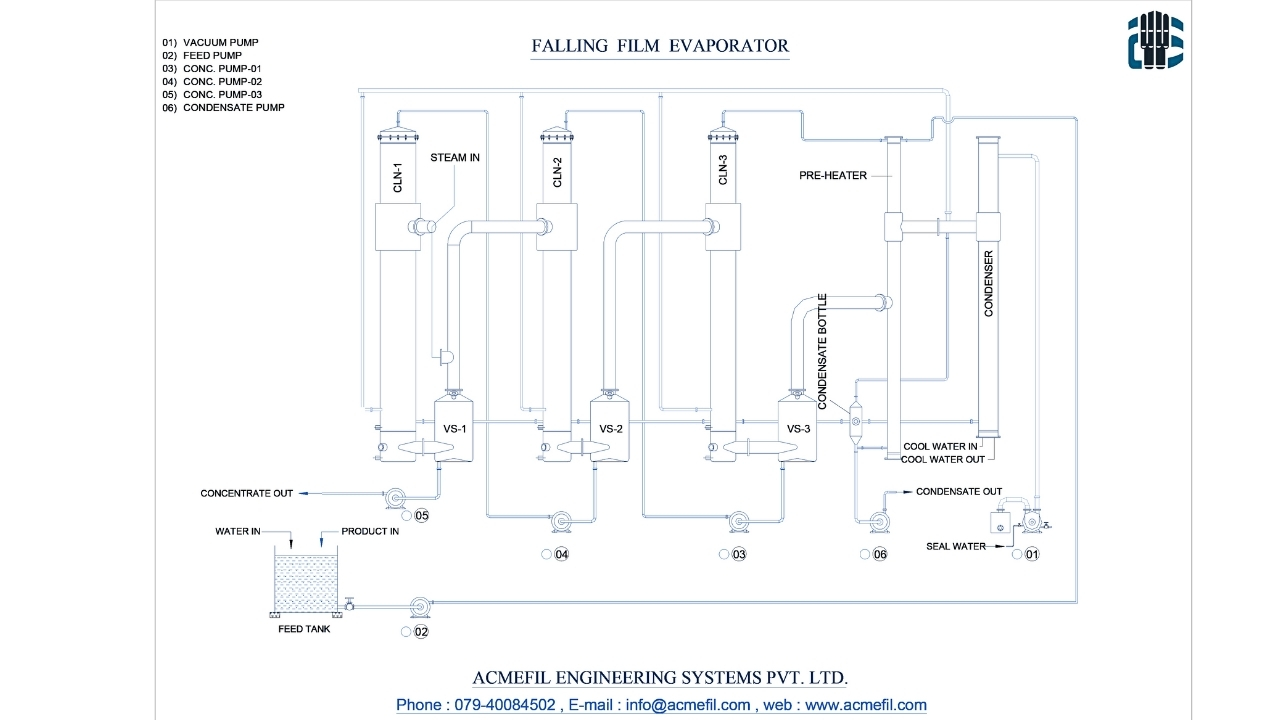

Falling film evaporators operate on a simple yet effective principle. We introduce the liquid to be evaporated at the top of the evaporator and distribute it evenly over the surface of a series of vertical tubes. These tubes are heated from the outside by steam or another heating medium. Here is a detailed step-by-step explanation of how falling film evaporators work:

Liquid Distribution: We start by feeding the liquid into the evaporator through an inlet at the top. We use a distributor to spread the liquid uniformly across the top of the heat exchange tubes, ensuring it forms an even, thin film as it flows down the inside surface of each tube.

Formation of a Thin Film: As the liquid descends, it forms a thin film over the surface of the tubes. This thin layer of liquid falls under the influence of gravity, providing a large surface area for efficient heat transfer and minimizing thermal resistance.

Heat Transfer and Evaporation: The external surface of the tubes is heated by steam or another heating medium. As the thin film of liquid flows downward, it absorbs heat from the tube walls, causing the liquid to evaporate primarily at the surface of the film. The constant renewal of the liquid film enhances this process, ensuring a high heat transfer coefficient.

Concentration and Separation: The evaporation of the solvent (usually water) from the liquid film results in the concentration of the solute. The generated vapor rises and exits the evaporator through the vapor outlet at the top, while the concentrated liquid continues to flow downward, exiting at the bottom of the evaporator.

Vapor-Liquid Separation: The generated vapor often contains entrained droplets of the liquid. To separate these droplets, we pass the vapor through a demister or an entrainment separator, removing the liquid droplets and allowing only the pure vapor to exit.

Condensation of Vapor: In many systems, we condense the vapor in a condenser, either for recovery of the solvent or for environmental reasons. We collect the condensed liquid and reuse or dispose of it as needed.

Control Systems: Modern falling film evaporators come equipped with advanced control systems that regulate the feed rate, heating temperature, and vacuum (if used). These controls optimize operation, maximizing efficiency and product quality while minimizing energy consumption and operational costs.

Falling film evaporators are particularly effective for heat-sensitive products because they operate at relatively low temperatures and short residence times. This minimizes thermal degradation and ensures the preservation of product quality.

Choosing the right manufacturer and supplier for your falling film evaporators is crucial. At Acmefil, we bring years of experience and expertise to the table, ensuring that our products meet the highest standards of quality and performance. Here’s why Acmefil is the leading choice for falling film evaporators:

At Acmefil, we don’t just sell you an evaporator; we provide comprehensive support to ensure smooth installation and operation. Our services include:

Ready to enhance your evaporation process with Acmefil’s falling film evaporators? Contact us today to discuss your needs and get a customized solution.

Falling film evaporators are a critical component in many industrial processes, offering unmatched efficiency, flexibility, and quality preservation. As a leading falling film evaporator manufacturer, Acmefil is committed to delivering top-notch solutions tailored to your specific needs. Trust Acmefil for all your evaporation requirements and experience the difference in quality and performance.

Consider factors such as the type of liquid to be evaporated, desired concentration levels, operational capacity, and energy efficiency. Our team at Acmefil can help you select the best model for your requirements.

Regular cleaning to remove scale buildup, periodic inspections to check for wear and tear, and timely replacement of any worn-out parts are essential for maintaining your evaporator’s efficiency.

Our evaporators maximize heat transfer and minimize energy consumption, offering significant energy savings over traditional methods.

Yes, falling film evaporators efficiently handle a wide range of viscosities, making them suitable for various applications.